C Marshall Fabrication Machinery, Inc., in no way condones war.

However, taking the silk purse from a sows ear approach to it, we can see some of the benefits of war if we look really hard, and usually not exactly where we might expect.

Take electroplating for example. In metal fabrication, electroplating is an everyday, taken for granted technology that is commonplace in our industry.

But being the inquisitive or bored mind writing this article (depending on who you talk to), I looked back and was surprised to find that the technology was discovered in 1805.

An inventive and industrious Italian chemist by the name of Luigi V Brugnatelli, using his colleague’s invention of the voltaic pile brought to being 5 years earlier, Luigi created the first environment of electrodeposition.

Unfortunately the technology was stomped on by the French Academy of Sciences for 30 years and it wasn’t until around 1839 that some British and Russian scientists independently started coming up with their own deposition processes very similar to Luigi’s.

They went forward to apply these sciences to copper electroplating of printing press plates.

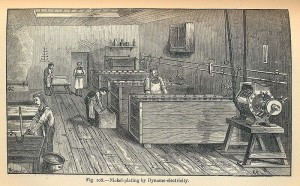

Then in 1876 the first modern electroplating plant was put into production in Hamburg.

The process itself grew and made great advances in the late 19th century with the use of electric generators, but the industry itself was limited by the lack of demand.

Until the World Wars that is.

The process then went from manually operated to wooden tanks to full on automated equipment cranking out thousands of kilograms per hour of parts, armor, etc.

Had to keep up with the demand of the war machines.

This of course led to technology of plating metal on plastic by physicist Richard Feynman.

I personally think that this could be refined a bit more. It didn’t take any time at for the chrome to where off of my volume knob in my truck.

Let’s keep working it boys! Stereo knobs alone are reason enough without having to go to war for incentive!