Guillotine Shear

A guillotine shear is a machine that can shear or cut various materials with a guillotine design. The word “guillotine” is associated with a blade that drops along a vertical track. This type of machine was primarily used in familiar history as a method of execution, particularly in the French Revolution, but the modern guillotine shear cutter is a tool used to form and shape products for a market.

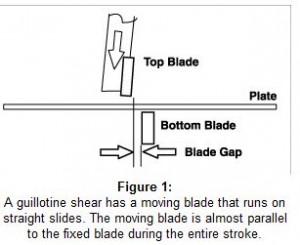

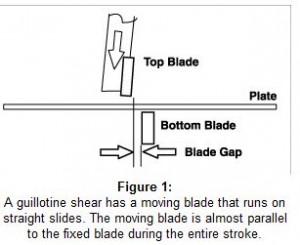

The principles of the guillotine shear were incorporated into the design of metal shears and have been the primary design for all of these years. Some of the shortcomings of a guillotine shear are that it must run in gibs and ways and therefore need a certain amount of clearance which has a direct effect on the thinnest sheet than can be cut (see figure 1).

Also, the ram moves down with approximately 1 degree of backward motion. This allows the cut sheet to clear the back gauge and drop, although sometimes even this is not enough and the cut part is wedged between the lower blade and the back gauge.

When a guillotine shear has a throat it must be heavily re-enforced to avoid the deflection that would normally result from a deep throat. The apron of the upper ram is heavily gusseted to keep the blades parallel to the bottom blades. This system has worked well for hundreds of years however times change and new engineering becomes available.

Swing Beam Shear

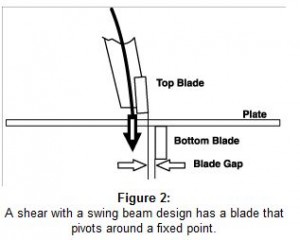

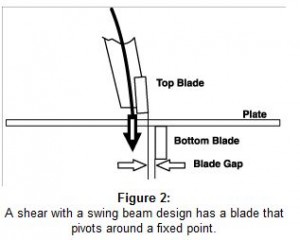

On a swing beam shear the ram moves on bearings so there is no play what so ever. This allows the swing beam shear to be able to cut paper as long as the blades are sharp. The ram moves from a fulcrum point in the rear of the side frames giving the shear a massive amount of plate between it and the cutting point (see figure 2). This means almost no detectable deflection.

The back gauge is attached to the bottom of the cutting column and moves up as the blade goes down. This means there will never be a possibility for the material to become stuck between the blade and the back gauge.

Rather than gussets on the apron a swing beam shear wraps the entire ram as one solid gusset making it much stronger than a similarly gusseted ram. It can have a deep throat with no possibility of deflection and can cut even the thickest piece of metal with a very low rake angle.

In my opinion the swing beam shear reviewed the short comings of the guillotine shear and fixed them; however, it is important to remember that before making a decision on purchasing any kind of a shearing machine factors such as the type of shear, required capacity, productivity options, and safety should be carefully evaluated.

One important consideration used in deciding what shear is the right one for any job is the capacity required to perform the job. Most of the shears on the market today list capacities for mild steel and stainless steel. It is advised to compare a fabricator’s requirements to those of the actual machine.

Some shear capacities are rated on mild steel, which may have 60,000 pounds per square inch (PSI) tensile strength, while others are rated for A-36 steel or 80,000 PSI tensile strength. Capacities for stainless steel are almost always less than those for mild or A-36 steel. Surprisingly enough certain grades of aluminum require as much power to shear steel does. As always, when making a decision on any kind of metalworking machinery purchase, it is important to work with a reputable and knowledgeable company that can answer all the questions regarding the performance and capacity for the machine.

From the desk of Cary Marshall

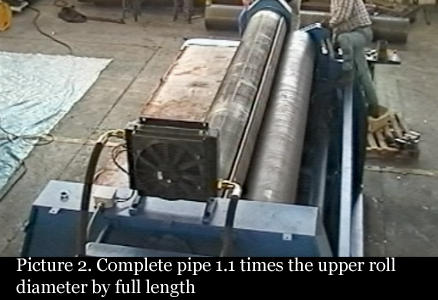

Metal-working companies who need to optimize their production look for a machine that can pre-bend and roll their metal efficiently to produce the products they in turn sell. We carry the MG line of rolling equipment; 4 roll hydraulic plate bending machines, 3 roll double pinch plate bending machines which both offer great benefits. We also have a 2 roll machine when extreme accuracy is required. The 4 roll machine offers great precision, productivity, versatility as well as speed, safety and ease of operation. For companies in the fabrication industry, they need top-quality machinery in order to maximize production and profits.

Metal-working companies who need to optimize their production look for a machine that can pre-bend and roll their metal efficiently to produce the products they in turn sell. We carry the MG line of rolling equipment; 4 roll hydraulic plate bending machines, 3 roll double pinch plate bending machines which both offer great benefits. We also have a 2 roll machine when extreme accuracy is required. The 4 roll machine offers great precision, productivity, versatility as well as speed, safety and ease of operation. For companies in the fabrication industry, they need top-quality machinery in order to maximize production and profits.