As part of my education in Anthropology at the University of Chicago, I had the opportunity to study up on different architectural styles of housing throughout the ages. Most established styles, of course, are derived from a function of design that works best in a particular geographical environment and that lends itself most easily to the tools, available resources and manufacturing processes of the time.

As part of my education in Anthropology at the University of Chicago, I had the opportunity to study up on different architectural styles of housing throughout the ages. Most established styles, of course, are derived from a function of design that works best in a particular geographical environment and that lends itself most easily to the tools, available resources and manufacturing processes of the time.

In spite of this, or maybe even in keeping with the inherent underlying practicalities of design, it still always bothered me that the vast majority of homes and houses are rectangular and not round.

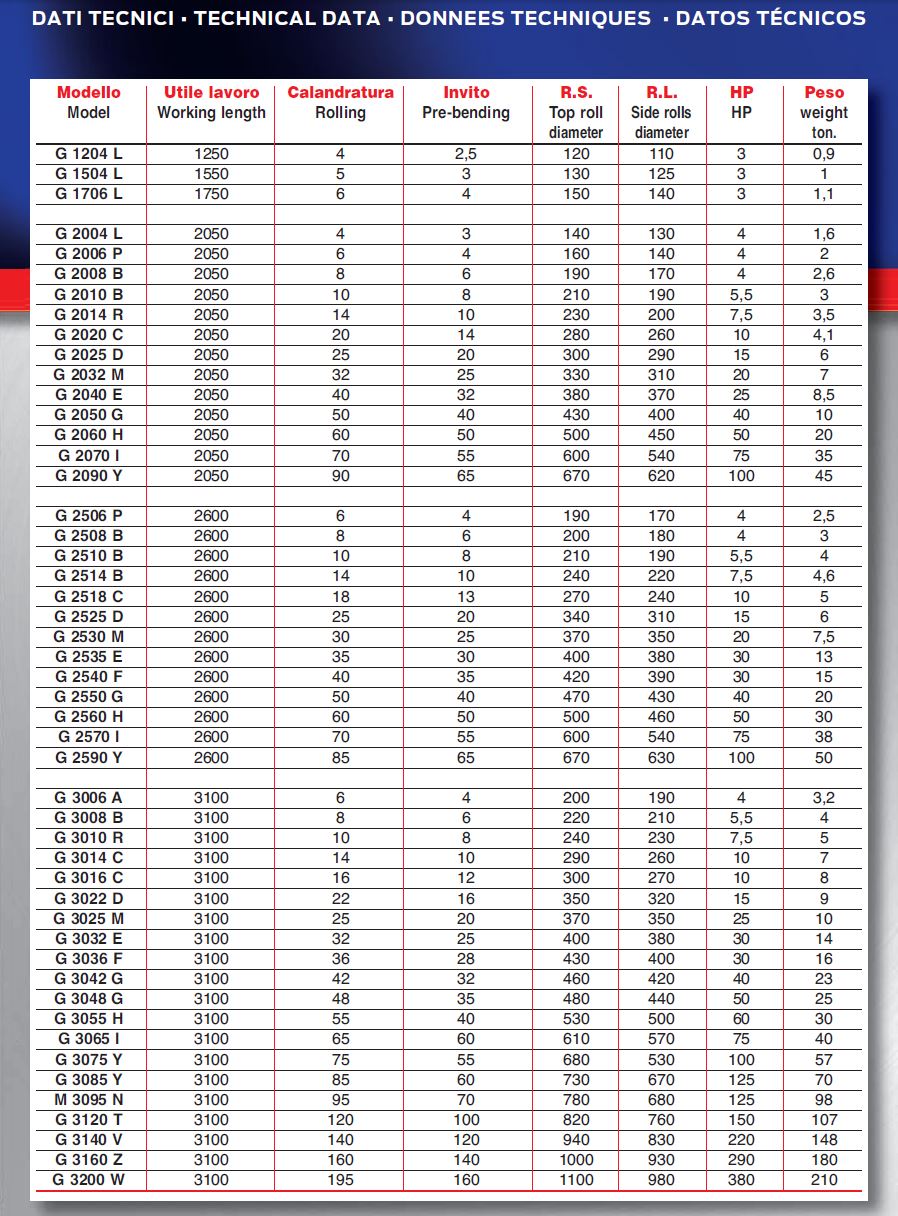

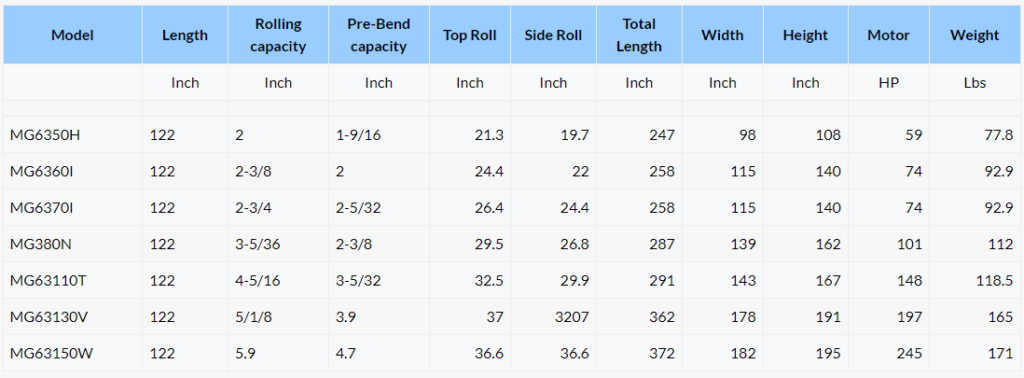

Considerations of the manufacturing process laid aside, I always thought that a house with rounded edges would be far more homey than a house with straight edges (insert Freudian comment referring to mother’s womb here). And yet, there are very few examples of architecture to date which accommodate this type of design. Could it be because it’s easier to make and intersect straight lines into a functional design? Possibly. I prefer to leave the manufacturing process to those who can do it. But, at least to my own untrained eye, existing technology for manufacturing rounded edges seems pretty prevalent (C Marshall Fabrication Machinery’s plate roll and EZ-Seam model WT 6/14 Weld Positioner being but two examples), so maybe in this day and age at least, it’s just a matter of bucking tradition.

I mean, they call it “thinking outside of the box” for a reason.

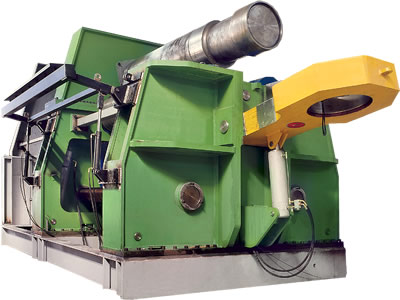

Enter the giant fuel storage tank.

Rumor has it that we will not always be as dependent on oil as we are now. Giant fuel storage tanks are not only an industrial marvel, but they are frequently the tallest structure on a landscape. Archaeologists have always been prone to assuming that the tallest man-made structures excavated were temples dedicated to the gods, rather than serving any practical function. In my not so humble opinion, a lot of these structures were falsely labeled as being exclusively places of worship. After all, if I had been around a few thousand years ago, I would’ve wanted the most bang for my buck, especially if the manufacturing tools of my trade consisted of crude hand-held and handmade instruments. If I was going to build a huge structure, I’d want to make sure it served a practical function – even if it was in addition to a religious or spiritual one.

Let’s fast-forward into a distant future, where our current ways of life have morphed into something completely different.

It’s likely that those giant cylindrical fuel storage tanks would still be standing. After all, they are leak-proof, fire-resistant, impact resistant and even bullet-proof. Could they too one day be interpreted as places of worship? Even if they were, it wouldn’t be too far off the mark, considering that today’s global economy and even international relations and wars are “fueled” by the demand for oil.

More importantly, I think these fuel storage tanks have kind of a unique, cozy appeal to them. That’s right, I think they’re cute. In fact, they bring out the Happy Susy Homemaker in me.

Let’s pretend we can clean them up pretty easily. Again, I’d defer to the industry experts to figure this out: if they can build these giant monoliths, cleaning them up should be relatively easy by comparison. In which case, we’d be left with a super-resilient, tall, round, hollow structure.

Now let’s insert a few floor plans. I’m thinking three floors total. I’m a little partial to wood flooring but I’d settle for bamboo or even tempered concrete. They actually look great with throw rugs on them. Kind of an urban-chic-meets-rustic-retreat kind of feel.

Throw in a bunch of windows, a few balconies just for fun and a pretty solar roof with ample skylights as well as a huge balcony up top, and finally a little elbow grease and a few coats of fresh paint, and there it is: my Barbie Doll dream home.

The fact that a lot of these storage tanks are already located in truly beautiful settings, including but not limited to prime waterfront, is also a nice plus.

Personally, I’m pretty convinced I’m a genius ahead of my time. If you think I’m completely off base here, or if this is the most impractical thing you’ve ever heard of, tell me why. But in closing, consider this: some of the best diners and mobile homes are made out of old railroad box cars and shipping containers. Of course, they’re not round, and they’re not bullet-proof.

Just sayin’.

Waterfront luxury townhome, anyone?

-Anja Wulf